Home » Products » Slashers & Rotary Cutters » Tri-Rotor Slasher | 200hp

Tri-Rotor Slasher | 200hp

Kanga farm equipment Tri-Rotor Slashers are a perfect solution for broadacre farmers in need of reliable and efficient equipment. Designed to cater to tractors ranging from 90 to 200 horsepower, these slashers enable you to effortlessly cover a wide area in a single pass.

Built right here in Australia for Australian conditions, our Tri-Rotor Slashers are equipped with a robust three-gearbox set-up with different ratios and horsepower options. Coupled with heavy-duty spring cushion couplings, this machine can effortlessly handle materials up to 50mm thick.

With our Tri-Rotor Slashers, you can confidently tackle tough vegetation and achieve efficient slashing results, all while enjoying the reliability and durability that comes from Australian manufacturing expertise.

Features

Compact in design, our Tri-Rotor Slashers boast a shorter front-to-rear profile, resulting in a wider cut width and enhanced maneuverability

6mm, square, clean-top deck

- Folded and fully reinforced

- Structural channel chassis

- 10mm side walls

- Clean top reduces the collection of debris and water

Deck side walls are welded and braced for strength when turning

Deck is hot-dip galvanized, for superior corrosion resistance and longevity

Anti-flex deck support frame

4.5m and 5.4m implements come standard with an anti-flex deck support frame. This support frame works in conjunction with the subframe and chassis to maintain a rigid deck

4.5m and 5.4m implements come standard with an anti-flex deck support frame. This support frame works in conjunction with the subframe and chassis to maintain a rigid deck

Featuring lowered overlapping Bisalloy oval disc rotors, our slashers allow for easy discharge of large volumes of material without compromising blade tip speed. This guarantees swift, clean and reliable slashing performance.

Disc rotors

- Three (3) 12mm BisAlloy oval steel disc

- Lowered, overlapping and timed, bolt-together design

Rounded corners on oval disc rotors and 360° spinning blades reduces impact related shock loads back through the drive train while the larger surface area helps the implement glide over obstacles such as check-banks, rocks and larger debris

Blades

- Stepped, suction, heat-treated, spring steel blades pivoting on hardened bushes

- 360° spinning

- Directional, rotating clockwise and anti-clockwise concurrently

- Oversize cup and pin blade bolt fixing system

- Reversible with tapered leading and trailing edges

- Braced for strength

- Positive locking with individual slots to maintain height

- Adjustable, four (4) positions (30mm increments)

Cutting height

50, 80, 110 and 140mm cutting heights

140mm – 300mm cutting height for topping paddocks is achievable using depth wheels

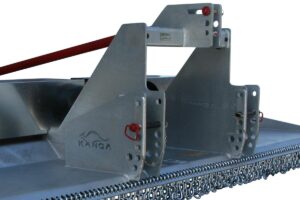

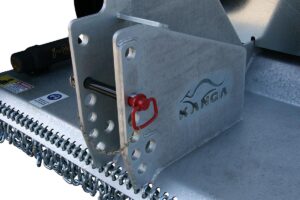

Category 2 and 3 linkage

Two-plate, double clevis mount designed to absorb lateral load and decrease metal fatigue when turning. Multiple mounting holes suit different tractors and quick-hitch systems

Centre-mounted tower position. Both slotted and round top link pin holes provide operators with the option of a floating or rigid tower mounting set-up

As a standard feature, twin wheels are fitted to the rear of the deck, providing a stable cutting platform. These rear wheels rotate 360°, maintaining consistent cut height during forward and reverse slashing operations.

- Height adjustment via a greaseable ratchet jack with a lock nut. Lock nut on the ratchet jack maintains cutting height

- 360° spinning wheel fork

- Heavy-duty solid cushion tyre with cast hub assembly

- Reinforced rectangular tube frame

- Nyloc lock nut to set pre-load on load bearing turn table discs

- Grease nipples for turn table discs and fork shaft for easy regular maintenance

Gearbox

The 4-way centre gearbox facilitates the 90° turn of power both laterally and vertically (down) required for tri-rotor cutters

Heavy-duty spring cushion couplings with a PTO shaft transfer power between the gearboxes, while Danish Value Springs absorb shock loads from blade impact, prolonging the life of gearboxes and the drive line. Shock loads in the middle gearbox are absorbed

by an over-run clutch.

PTO

Series W2600 PTO shaft with 200mm (8”) friction over-run clutch

Lever release PTO Shaft Guards facilitate safe engagement of yokes and easy joint maintenance

Protection

Front and rear chain curtain is incorporated into the deck for maximum safety, with a unique wire rope replacement system

Blade exclusion zone for safety to prevent accidental contact with blades

Waterproof manual holder

Features

Compact in design, our Tri-Rotor Slashers boast a shorter front-to-rear profile, resulting in a wider cut width and enhanced maneuverability

6mm, square, clean-top deck

- Folded and fully reinforced

- Structural channel chassis

- 10mm side walls

- Clean top reduces the collection of debris and water

Deck side walls are welded and braced for strength when turning

Deck is hot-dip galvanized, for superior corrosion resistance and longevity

Anti-flex deck support frame

4.5m and 5.4m implements come standard with an anti-flex deck support frame. This support frame works in conjunction with the subframe and chassis to maintain a rigid deck

4.5m and 5.4m implements come standard with an anti-flex deck support frame. This support frame works in conjunction with the subframe and chassis to maintain a rigid deck

Featuring lowered overlapping Bisalloy oval disc rotors, our slashers allow for easy discharge of large volumes of material without compromising blade tip speed. This guarantees swift, clean and reliable slashing performance.

Disc rotors

- Three (3) 12mm BisAlloy oval steel disc

- Lowered, overlapping and timed, bolt-together design

Rounded corners on oval disc rotors and 360° spinning blades reduces impact related shock loads back through the drive train while the larger surface area helps the implement glide over obstacles such as check-banks, rocks and larger debris

Blades

- Stepped, suction, heat-treated, spring steel blades pivoting on hardened bushes

- 360° spinning

- Directional, rotating clockwise and anti-clockwise concurrently

- Oversize cup and pin blade bolt fixing system

- Reversible with tapered leading and trailing edges

- Braced for strength

- Positive locking with individual slots to maintain height

- Adjustable, four (4) positions (30mm increments)

Cutting height

50, 80, 110 and 140mm cutting heights

140mm – 300mm cutting height for topping paddocks is achievable using depth wheels

Category 2 and 3 linkage

Two-plate, double clevis mount designed to absorb lateral load and decrease metal fatigue when turning. Multiple mounting holes suit different tractors and quick-hitch systems

Centre-mounted tower position. Both slotted and round top link pin holes provide operators with the option of a floating or rigid tower mounting set-up

As a standard feature, twin wheels are fitted to the rear of the deck, providing a stable cutting platform. These rear wheels rotate 360°, maintaining consistent cut height during forward and reverse slashing operations.

- Height adjustment via a greaseable ratchet jack with a lock nut. Lock nut on the ratchet jack maintains cutting height

- 360° spinning wheel fork

- Heavy-duty solid cushion tyre with cast hub assembly

- Reinforced rectangular tube frame

- Nyloc lock nut to set pre-load on load bearing turn table discs

- Grease nipples for turn table discs and fork shaft for easy regular maintenance

Gearbox

The 4-way centre gearbox facilitates the 90° turn of power both laterally and vertically (down) required for tri-rotor cutters

Heavy-duty spring cushion couplings with a PTO shaft transfer power between the gearboxes, while Danish Value Springs absorb shock loads from blade impact, prolonging the life of gearboxes and the drive line. Shock loads in the middle gearbox are absorbed

by an over-run clutch.

PTO

Series W2600 PTO shaft with 200mm (8”) friction over-run clutch

Lever release PTO Shaft Guards facilitate safe engagement of yokes and easy joint maintenance

Protection

Front and rear chain curtain is incorporated into the deck for maximum safety, with a unique wire rope replacement system

Blade exclusion zone for safety to prevent accidental contact with blades

Waterproof manual holder

Specifications

Code | KTH200 - 3.6 | KTH200 - 4.5 | KTH200 - 5.4 |

|---|---|---|---|

| Size reference | 3.6m | 12’ | 4.5m | 15’ | 5.4m | 18’ |

| Tractor range (hp) | 90-200 | 75-167 @ PTO | 100-200 | 84-167 @ PTO | 110-200 | 92-167 @ PTO |

| Gearbox | 200hp, 1000rpm | 200hp, 1000rpm | 200hp, 1000rpm |

| Blade tip speed (ft/min) | 18,440 | 13,610 | 16,380 |

| Overall width (mm) | 3720 | 4620 | 5520 |

| Cutting width (mm) | 3520 | 4420 | 5320 |

| Price (inc. GST) | $39,000 | $42,000 | $45,000 |

| Price (inc. GST) | $49,091 | $52,868 | $56,644 |

| Price (inc. GST) | $42,900 | $46,200 | $49,500 |

Options

Code | Description | Price (inc. GST) | Price (inc. GST) | Price (inc. GST) |

|---|---|---|---|---|

| KTHFLEX | FLEX modification* | for orchards with delving rows | suits all | $3,500 | $3,525 | $3,850 |

| KTH-TSD | Twin side discharge modification* | suits all tri-head slashers | $1,500 | $1,511 | $1,650 |

Flex modification

Farm Implements offers the option to order this implement with a drop centre configuration. In situations where there is a delve between the rows of plants, this FLEX wing modification allows the implement to cut at a more consistent height on undulating land, compared to a rigid-deck implement.

Twin-side discharge

Farm Implements offers the option to order this implement with twin-side discharge. This modification discharges the cut material as mulch, laterally under vines or orchard trees. Side discharge prevents windrows between rows and benefits plantings by suppressing weed growth, top soil erosion and moisture evaporation.

* only available at time of order. Cannot be retro-fitted. Operator can order Flex modification or Twin-side discharge or Flex modification with Twin-side discharge.

Parts

Code | Description | Price (inc. GST) | Price (inc. GST) | Price (inc. GST) |

|---|---|---|---|---|

| 220.086-S360 | Suction blade | 360° rotation | left | each | suits all | $80 | $106 | $80 |

| 220.087-S360 | Suction blade | 360° rotation | right | each | suits all | $80 | $106 | $80 |

| 100.188 | 7/8 Oval rotor bolt kit | kit (1 x bolt, nut, bush) | each (per blade) | suits all | $99 | $131 | $99 |

Need more information? Contact us here