Home » Products » Slashers & Rotary Cutters » H Range Rotary Cutter | Cutter Bar

H Range Rotary Cutter | Cutter Bar

Since 1983, the Kanga farm equipment H Range Rotary Cutters have been trusted and recommended by our dealers, establishing a reputation as reliable, robust, and high-performing machines. Designed to handle challenging Australian conditions, the H Range is well suited to a diverse range of applications. Whether it’s farmers clearing thick scrub and regrowth or contractors cutting roadsides and maintaining mining sites or government land, these cutters deliver exceptional performance in any task.

The 5mm deck of our H Range Rotary Cutters is fully reinforced underneath, featuring a clean-top design that minimises debris and water collection, ensuring longevity and uninterrupted operation even in harsh environments.

Available with a Sandwich Design Cutter Bar or Disc Rotor.

Features

5mm, round-back, clean-top deck

- Round-back design increases maneuverability

- Clean top reduces the collection of debris and water

Deck side walls are welded and braced for strength when turning

Gearbox mounting plate is welded to the subframe, creating greater structural integrity, in the event of load torque caused by blade impact

Deck is hot-dip galvanized, for superior corrosion resistance and longevity

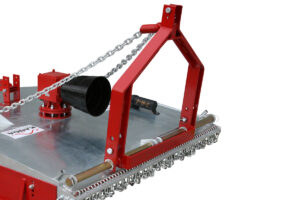

Our Original Three-Bar Sandwich Design Cutter Bar

The Cutter Bar option offers a lowered, reinforced 130mm spring steel cutter bar. Created by heat-treating and tempering high-tensile steel, spring steel has high strength and high elasticity and ‘springs’ back to its original form after impact. Powered by a high-ratio gearbox, the reduced surface area of the cutter bar enables swift and efficient cutting and discharge of a larger volume of material.

- Lowered, bolt-together sandwich design

- 130mm wide, high-tensile/spring steel

- Powered by T piece with drive lugs

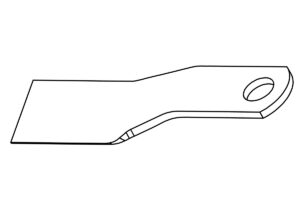

Blades

Countersunk bolts secure the blades, preventing wear and tear and facilitating easy maintenance. Simply unfasten the lock nut to replace blades during the implement’s lifetime.

Two (2) stepped, suction, heat-treated, spring steel blades pivoting on hardened bushes

Blade bolt inspection cap allows operator to check blades and blade bolts from the top of the implement

Skids

- Reversible, removable side skids with tapered leading and trailing edges

- Braced for strength

- Positive-locking with individual bolt holes to maintain height

- Adjustable, four (4) positions (30mm increments)

Cutting height

50, 80, 110 and 140mm cutting heights

Category 1 and 2 linkage

Two-plate, double clevis mount designed to absorb lateral load and decrease metal fatigue when turning

Tower chain mounting points are welded to the subframe and braced on the deck

Chain stays allow for tower movement, forward and aft, to maintain an even cut over undulating ground

Tower adjustment

- Multiple tower positions; in the centre-mounted position the implement is directly behind the tractor. In the offset position, the implement extends out left or right.

- Tower position can be adjusted without the need of tools thanks to the chain tube holder and sliding tower bar

- Tower is held in position with shaft locking pins

PTO

Series 8 Integral clutch & shaft or Series W2600 Integral clutch & shaft

Lever release PTO Shaft Guards facilitate safe engagement of yokes and easy joint maintenance

Protection

Front and rear chain curtain is incorporated into the deck for maximum safety, with a unique wire rope replacement system

Blade exclusion zone for safety to prevent accidental contact with blades

Waterproof manual holder

Features

5mm, round-back, clean-top deck

- Round-back design increases maneuverability

- Clean top reduces the collection of debris and water

Deck side walls are welded and braced for strength when turning

Gearbox mounting plate is welded to the subframe, creating greater structural integrity, in the event of load torque caused by blade impact

Deck is hot-dip galvanized, for superior corrosion resistance and longevity

Our Original Three-Bar Sandwich Design Cutter Bar

The Cutter Bar option offers a lowered, reinforced 130mm spring steel cutter bar. Created by heat-treating and tempering high-tensile steel, spring steel has high strength and high elasticity and ‘springs’ back to its original form after impact. Powered by a high-ratio gearbox, the reduced surface area of the cutter bar enables swift and efficient cutting and discharge of a larger volume of material.

- Lowered, bolt-together sandwich design

- 130mm wide, high-tensile/spring steel

- Powered by T piece with drive lugs

Blades

Countersunk bolts secure the blades, preventing wear and tear and facilitating easy maintenance. Simply unfasten the lock nut to replace blades during the implement’s lifetime.

Two (2) stepped, suction, heat-treated, spring steel blades pivoting on hardened bushes

Blade bolt inspection cap allows operator to check blades and blade bolts from the top of the implement

Skids

- Reversible, removable side skids with tapered leading and trailing edges

- Braced for strength

- Positive-locking with individual bolt holes to maintain height

- Adjustable, four (4) positions (30mm increments)

Cutting height

50, 80, 110 and 140mm cutting heights

Category 1 and 2 linkage

Two-plate, double clevis mount designed to absorb lateral load and decrease metal fatigue when turning

Tower chain mounting points are welded to the subframe and braced on the deck

Chain stays allow for tower movement, forward and aft, to maintain an even cut over undulating ground

Tower adjustment

- Multiple tower positions; in the centre-mounted position the implement is directly behind the tractor. In the offset position, the implement extends out left or right.

- Tower position can be adjusted without the need of tools thanks to the chain tube holder and sliding tower bar

- Tower is held in position with shaft locking pins

PTO

Series 8 Integral clutch & shaft or Series W2600 Integral clutch & shaft

Lever release PTO Shaft Guards facilitate safe engagement of yokes and easy joint maintenance

Protection

Front and rear chain curtain is incorporated into the deck for maximum safety, with a unique wire rope replacement system

Blade exclusion zone for safety to prevent accidental contact with blades

Waterproof manual holder

Specifications

Code | KSHR180-CB | KSHR180-CB/PTO | KSHR210-CB | KSHR210-CB/PTO |

|---|---|---|---|---|

| Size reference | 1.8m | 6’0” | 72” | 1.8m | 6’0” | 72” | 2.1m | 7’0” | 84” | 2.1m | 7’0” | 84” |

| Tractor range (hp) | 80-120 | 67-100 @ PTO | 80-120 | 67-100 @ PTO | 90-130 | 75-109 @ PTO | 90-130 | 75-109 @ PTO |

| Gearbox | 130hp, 540rpm, 1:1.92 ratio | 130hp, 540rpm, 1:1.92 ratio | 130hp, 540rpm, 1:1.46 ratio | 130hp, 540rpm, 1:1.46 ratio |

| Blade tip speed (ft/min) | 19,560 | 19,560 | 17,370 | 17,370 |

| Overall width (mm) | 2040 | 2040 | 2335 | 2335 |

| Cutting width (mm) | 1800 | 1800 | 2100 | 2100 |

| Weight (kg) | 610 | 620 | 705 | 715 |

| Price (inc. GST) | $10,750 | $11,250 | $11,750 | $12,250 |

| Price (inc. GST) | $11,925 | $12,588 | $13,250 | $13,913 |

| Price (inc. GST) | $11,825 | $12,375 | $12,925 | $13,475 |

Options

Code | Description | Price (inc. GST) | Price (inc. GST) | Price (inc. GST) |

|---|---|---|---|---|

| KHRDW | Heavy-duty depth wheel | each | suits all | $1,250 | $1,259 | $1,375 |

Parts

Code | Description | Price (inc. GST) | Price (inc. GST) | Price (inc. GST) |

|---|---|---|---|---|

| 100.134 | STANDARD stepped suction blades | pair (2-pieces) | suits all | $80 | $106 | $80 |

| 100.135 | 3/4” blade bolt kit | kit (2 x bolt, nut, bush) | suits all | $35 | $46 | $35 |

| 100.136 | 7/8” blade bolt kit | kit (2 x bolt, nut, bush) | suits Pre-2008 Cutters | $60 | $80 | $60 |

| 100.106-XH | 1.8m H Range cutter bar | 3-piece cutter bar | suits KSHR180-CB & CB/PTO | $880 | $1,170 | $880 |

| 100.102-XH | 2.1m H Range cutter bar | 3-piece cutter bar | suits KSHR210-CB & CB/PTO | $990 | $1,320 | $990 |

Need more information? Contact us here